Auto-to-manual transmission conversion kits enable drivers to switch from automatic to manual transmissions‚ offering enhanced control and performance. These kits typically include essential components like transmission mounts‚ shifter towers‚ and clutch pedal assemblies‚ designed to simplify the transition while maintaining vehicle compatibility and functionality. They cater to enthusiasts seeking a more engaging driving experience‚ allowing customization to fit specific vehicle requirements and performance goals.

1.1 Overview of Transmission Conversion

Transmission conversion involves replacing an automatic transmission with a manual system‚ offering improved driver engagement and control. Conversion kits provide necessary components like shifter towers‚ clutch pedals‚ and adapter plates. These kits are tailored for specific vehicles‚ such as the Nissan 350Z or BMW E46‚ ensuring compatibility and performance. The process typically requires mechanical expertise but allows for customization to suit individual driving preferences. The goal is to enhance the driving experience by transitioning to a manual setup‚ catering to enthusiasts who value precision and responsiveness behind the wheel.

1.2 Importance of Conversion Kits

Conversion kits are essential for a seamless transition from automatic to manual transmission‚ providing all necessary components tailored to specific vehicles. They ensure compatibility and simplify installation‚ offering enhanced performance and reliability. These kits cater to enthusiasts seeking better control and driving engagement. By including parts like transmission mounts and clutch assemblies‚ they eliminate the need for sourcing individual components. Conversion kits are a comprehensive solution‚ enabling drivers to achieve a manual setup without compromising functionality or vehicle integrity.

Key Components of an Auto to Manual Conversion Kit

Key components include transmission mount‚ shifter tower‚ clutch pedal assembly‚ adapter plate‚ reverse wiring pigtail‚ and neutral safety switch. They ensure compatibility and proper functionality during the conversion process.

2.1 Transmission Mount

The transmission mount is a crucial component in an auto-to-manual conversion kit‚ ensuring proper alignment and stability between the manual transmission and the vehicle’s chassis. It is specifically designed to accommodate the structural differences between automatic and manual transmissions‚ providing a secure and vibration-dampening connection. This mount prevents excessive movement and noise‚ ensuring smooth operation and longevity of the transmission. Proper installation is essential to maintain drivetrain integrity and optimal performance.

2.2 Shifter Tower and Lever

The shifter tower and lever are essential for enabling manual gear changes in a converted vehicle. Designed to replace the automatic shifter‚ the tower is mounted directly to the transmission‚ while the lever connects to the shift linkage. These components ensure precise control over gear selection‚ offering a smooth and responsive shifting experience. Available in OEM or aftermarket configurations‚ they can be customized to fit specific vehicle needs‚ enhancing both functionality and driver engagement during the conversion process.

2.3 Clutch Pedal Assembly

The clutch pedal assembly is a critical component in an auto-to-manual conversion‚ enabling the driver to engage and disengage the clutch smoothly. It typically includes a pedal pad‚ master cylinder‚ and linkage system. Designed to integrate seamlessly with the manual transmission‚ the assembly ensures precise control over the clutch operation‚ allowing for effortless shifting between gears. High-quality materials and precise engineering make it durable and reliable‚ essential for both performance and driver comfort during the conversion process.

2.4 Adapter Plate and Cam Seal

The adapter plate and cam seal are essential for ensuring a secure connection between the manual transmission and the engine. The adapter plate aligns the transmission with the engine’s bellhousing‚ while the cam seal prevents oil leaks at the transmission input shaft. These components are precision-engineered to maintain proper fitment and functionality. High-quality materials‚ such as steel or aluminum‚ are often used for durability. The adapter plate and cam seal are crucial for a leak-free and vibration-free manual transmission conversion‚ ensuring smooth operation and longevity of the system.

2.5 Reverse Wiring Pigtail

The reverse wiring pigtail is a critical component in auto-to-manual conversion kits‚ enabling the correct electrical connections for the manual transmission. It adapts the vehicle’s wiring harness to the manual transmission’s electronic controls‚ ensuring functions like reverse lights and transmission communication operate seamlessly. This pigtail simplifies the wiring process‚ preventing errors and ensuring compatibility. Proper installation of the reverse wiring pigtail guarantees that all electrical systems function as intended‚ maintaining safety and performance during the conversion process.

2.6 Neutral Safety Switch

The neutral safety switch is a vital component in auto-to-manual conversion kits‚ ensuring the vehicle starts only in neutral or when the clutch pedal is pressed. This switch prevents accidental engine startup in gear‚ enhancing safety and preventing potential damage to the transmission or drivetrain. Typically installed near the clutch pedal assembly‚ it integrates seamlessly with the vehicle’s electrical system. Proper installation is crucial to maintain functionality and safety‚ making it a key element in the conversion process.

Benefits of Converting to Manual Transmission

Converting to manual transmission enhances fuel efficiency‚ improves performance‚ and reduces long-term maintenance costs. It also increases driver engagement‚ offering better control and a more rewarding driving experience.

3.1 Improved Performance and Control

Switching to a manual transmission significantly enhances vehicle performance and control. Manual transmissions offer quicker acceleration and precise gear shifts‚ allowing drivers to optimize power delivery. This results in better responsiveness‚ especially during spirited driving or on winding roads. Additionally‚ manual transmissions eliminate the lag often associated with automatics‚ providing a more direct connection between the driver and the vehicle. This improved control and responsiveness make driving more engaging and enjoyable for enthusiasts seeking a more hands-on experience behind the wheel.

3.2 Enhanced Driver Engagement

Converting to a manual transmission fosters a deeper connection between the driver and the vehicle. The physical act of shifting gears and using the clutch engages more of the driver’s senses and skills‚ creating a more immersive driving experience. This increased involvement heightens situational awareness and makes driving more rewarding‚ especially for enthusiasts who value precision and control. The tactile feedback and mechanical interaction with the car’s components provide a sense of accomplishment and satisfaction that automatic transmissions often lack‚ making every drive more engaging and enjoyable.

3.3 Potential Cost Savings

Converting to a manual transmission can offer long-term financial benefits; Manual transmissions typically require less complex and costly repairs compared to automatics‚ reducing maintenance expenses over time. Additionally‚ manuals often achieve better fuel efficiency‚ especially in city driving‚ which can lower fuel costs. While the initial conversion investment may seem high‚ the savings from reduced repair bills and improved mileage can offset these costs in the long run‚ making it a financially viable option for budget-conscious drivers seeking durability and efficiency.

Step-by-Step Installation Guide

A comprehensive guide outlines the process‚ from preparing tools to installing the manual transmission‚ ensuring a smooth transition with detailed instructions for each step.

4.1 Preparation and Tools Required

Begin by gathering essential tools and materials‚ including a socket set‚ wrenches‚ and specialized tools like a clutch alignment tool. Ensure you have a vehicle lift or jack stands for safe access. Collect the conversion kit components‚ such as the transmission mount‚ shifter tower‚ and clutch pedal assembly. Verify compatibility with your vehicle’s make and model‚ and prepare any additional hardware like adapter plates or wiring harnesses. Consult a repair manual for specific instructions and check for any vehicle-specific requirements‚ such as crossmembers or driveshafts‚ to ensure a smooth installation process.

4.2 Removing the Automatic Transmission

Start by disconnecting the electrical connectors and fluid lines from the automatic transmission. Drain the transmission fluid and safely collect it for proper disposal. Next‚ remove the transmission cooler lines and any brackets or mounts securing the transmission. Use a jack or transmission jack to support the unit‚ then remove the mounting bolts. Carefully lift the transmission out of the vehicle‚ taking note of any components like the torque converter that may need to be separated. Ensure all electrical connectors and linkages are cleared before completely removing the transmission.

4.3 Installing the Manual Transmission

Installing the manual transmission involves aligning it with the engine‚ ensuring proper fitment using the adapter plate provided in the conversion kit. Bolt the transmission to the engine‚ following the kit’s instructions for precise alignment. Connect the clutch pedal assembly to the transmission‚ ensuring the linkage is secure and properly adjusted for smooth operation. Install new mounts if necessary‚ typically included in the kit‚ to support the manual transmission. Disconnect any unnecessary electrical connectors from the automatic transmission and consult the kit’s guide for wiring adjustments. Secure the manual shifter and adjust the linkage for optimal shifting. Verify the driveshaft compatibility or modify it as needed to ensure proper fitment and functionality.

4.4 Connecting the Clutch and Pedal Assembly

Connect the clutch pedal assembly to the manual transmission‚ ensuring the master and slave cylinders are properly aligned and installed. Use the adapter plate and cam seal provided in the kit to secure the clutch system to the transmission. Bleed the hydraulic system to remove air bubbles and ensure smooth clutch engagement. Adjust the pedal assembly for proper travel and engagement‚ following the kit’s instructions. Once installed‚ test the clutch operation to confirm it disengages and engages smoothly before finalizing the setup.

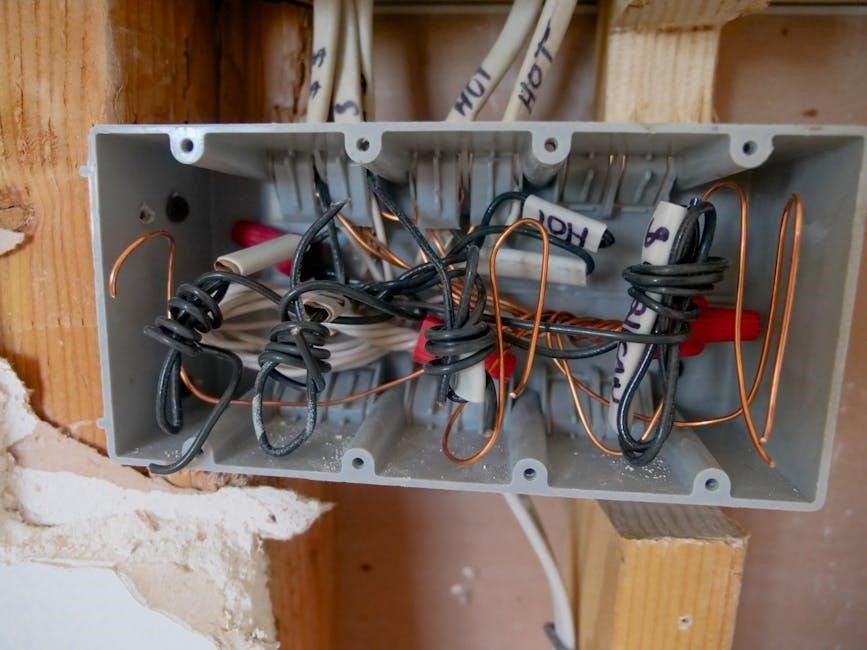

4.5 Wiring and Electrical Connections

Connect the reverse wiring pigtail to the manual transmission and integrate it with the vehicle’s electrical system. Install the neutral safety switch to ensure the engine only starts in neutral gear. Modify the existing wiring harness to accommodate the manual transmission controls‚ such as the clutch pedal and shifter. Use the provided connector kits to simplify wiring connections. Ensure all electrical components are securely fastened and tested for proper function before completing the installation.

Common Challenges and Solutions

Converting from auto to manual often involves compatibility issues‚ mechanical adaptations‚ and electrical wiring complexities. Solutions include using specialized kits‚ consulting forums‚ and seeking professional assistance when needed.

5.1 Compatibility Issues

Compatibility issues arise when components from automatic and manual transmissions don’t align. For instance‚ the bellhousing‚ clutch system‚ and drivetrain may require modifications. Ensuring the correct adapter plate and cam seal is crucial. Additionally‚ the electrical system must be reconfigured to accommodate the manual setup; Using specialized kits designed for specific vehicle models can mitigate these issues. Consulting forums or professionals is often necessary to resolve complex incompatibilities and ensure a seamless conversion process. Proper planning and research are essential to avoid costly mistakes.

5.2 Mechanical and Electrical Adaptations

Mechanical and electrical adaptations are critical during an auto-to-manual conversion. The transmission mount‚ shifter tower‚ and clutch pedal must be precisely aligned. Wiring adjustments are necessary to disable automatic-specific sensors and integrate manual components. The neutral safety switch and reverse wiring pigtail often require reconfiguration. Hydraulic or mechanical linkages for the clutch system must be installed. These adaptations ensure proper functionality and safety‚ requiring careful planning and execution to maintain vehicle performance and reliability post-conversion.

5.3 Troubleshooting Post-Installation Problems

Post-installation issues may arise‚ such as clutch slippage or gear misalignment. Verify clutch pedal adjustment and ensure proper hydraulic line bleeding. Electrical faults like incorrect wiring or sensor malfunctions can cause transmission errors. Check the neutral safety switch and reverse wiring pigtail connections. Grinding gears may indicate improper shifter tower alignment or lack of clutch engagement. Professional assistance is recommended for persistent problems to ensure reliability and prevent further damage. Thorough diagnostics are essential for a smooth transition post-conversion.

Converting to a manual transmission offers improved performance‚ driver engagement‚ and cost savings. With proper installation and troubleshooting‚ enthusiasts can achieve a seamless and rewarding driving experience.

6.1 Final Thoughts on Auto to Manual Conversion

Auto-to-manual conversion kits offer a transformative driving experience‚ blending enhanced performance‚ control‚ and engagement. While the process requires careful planning and expertise‚ the results are rewarding. Drivers benefit from improved fuel efficiency‚ lower maintenance costs‚ and a more connected feel behind the wheel. As automotive technology evolves‚ these kits continue to gain popularity‚ providing enthusiasts with a practical solution to achieve their desired driving dynamics. Proper installation and post-conversion care are crucial for long-term satisfaction and reliability.

6.2 Future of Transmission Conversion Technology

The future of transmission conversion technology promises innovation and accessibility‚ with manufacturers like TREMEC and Modern Driveline leading advancements. Enhanced plug-and-play kits are expected to simplify installations‚ reducing complexity for enthusiasts. Lightweight materials and improved compatibility will expand options for various vehicles. Additionally‚ the rise of hybrid and electric vehicles may inspire new conversion solutions‚ blending manual control with modern efficiency. As demand grows‚ the market will likely offer more tailored and user-friendly transmission conversion kits‚ catering to both classic and contemporary automotive applications.